Installation & Floorcare

In our Installation & floorcare section you will be able to find which type of adhesives, cleaning products, covings and more, you could use for our flooring products. We also provide several video's that will show you how to install some of our products & how to perform several floorcare methods to keep our products performing at the best of their capabilities.

-

Chatbot

24/7 support

-

Marmoleum

Installation & Floorcare

-

Project Vinyl

Installation & Floorcare

-

Flotex Flocked Flooring

Installation & Floorcare

-

Carpet Tiles

Installation & Floorcare

-

Coral Textile Entrance Flooring Systems

Installation & Floorcare

-

.webp)

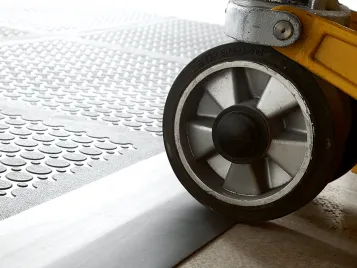

Nuway Rigid Entrance Flooring Systems

INSTALLATION & FLOORCARE

-

ESD & Cleanroom Flooring

Installation & Floorcare

-

Modul'up

Adhesive Free Vinyl